The accessibility and ease of working with the Fluent module of ANSYS and OpenFOAM were considered. The study of external vehicle aerodynamics using Spalart-Allmaras turbulence model with adjoint method was conducted. Keywords: computational fluid dynamics (CFD), In terms of accuracy and computational cost, the SST k-ω turbulence model is observed to be the most efficient. The performance cross-comparison of the k-ϵ model, Reynolds stress model (RSM) and shear-stress transport (SST) k-ω turbulence model is made in the study. The choice of turbulence model is nontrivial in the multiphase flow modelling in a venturi. The simulation results are compared with experimental measurements of venturi differential pressure and chord-averaged gas holdup in the venturi throat section. A steady Eulerian-Eulerian framework is used to simulate upward gas-liquid flow in a vertical venturi. Having a robust computational model for multiphase flow in a venturi is desirable for understanding the gas-liquid and fluid-pipe interactions and predicting pressure and phase distributions under various flow conditions. This entry was posted in Simulation, SOLIDWORKS and tagged Flow Simulation vs Hand Calculations, Simulation vs Hand Calculations, SOLIDWORKS, SOLIDWORKS Simulation.A venturi flowmeter is a common device used in multiphase flow rate measurement in the upstream oil and gas industry.

SOLIDWORKS FLOW SIMULATION TURBULENCE MODELS SOFTWARE

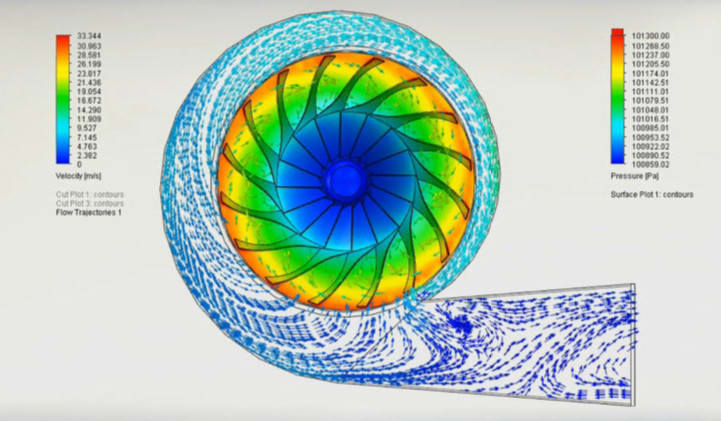

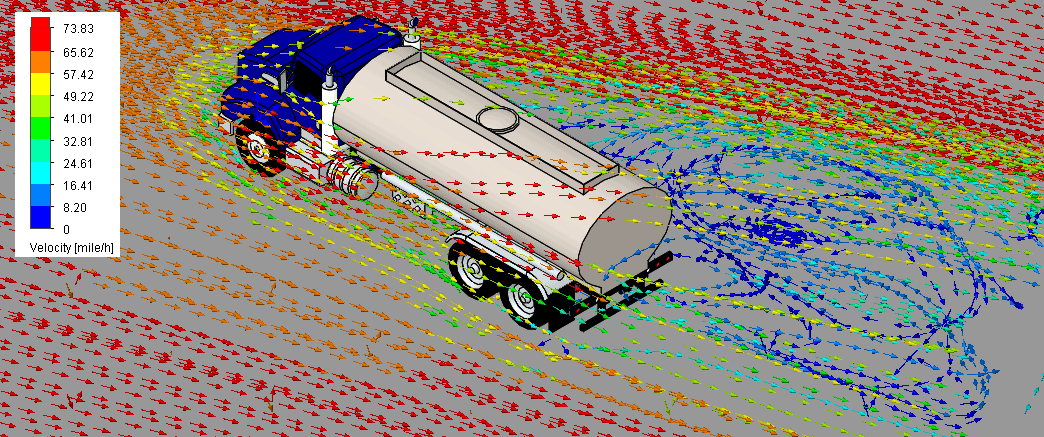

From this you should see how powerful and capable the software is over a broad range of studies. These are just a few examples of what SOLIDWORKS flow has to offer not including radiation, heat transfer in solids, cooling of electrical equipment. From this we can see the known effects of travelling at supersonic speeds. This complex study took thousands of iterations and a reduced mesh density to reduce solve time. The study below was ran with a wind speed of 410 m/s making it supersonic flow. It also has an option to study high mach number flow. SOLIDWORKS flow is capable of accurately simulating flow in the laminar and turbulent stages. This is visible in a static study but using Animation within SOLIDWORKS we can visualize better with a transient study. Increasing the velocity again we can start to see vortices being shed. In this study we can see the build of vortices at the rear of the cylinder. We can see the separation of the boundary layer towards the back of the cylinder, this area has slightly less pressure than the same point in the front of the cylinder. Here we can see at very low Reynolds number that the flow does not separate and the pressure gradient pushes the flow around the body.

The three examples below show steady state flow at different velocities of air. For low Reynolds numbers this will be around the cylinder, but for larger to see the vortices the computational domain extends past the model. To do this I modelled a cylinder of diameter 50mm with an extrusion of 200mm, the extrusion length is arbitrary as I used a 2D computational domain.Įditing the definition of the domain to better show the areas of interest. In this section I will take a look at recreating some results from these studies to show the difference in Reynolds number to the flow. There are numerous peer reviewed studies on the effects of flow around bluff bodies. In the next example we will discuss external flow over a bluff body. We can see the validation for a very simple section of pipe. We can then set a surface goal to get the velocity at the outlet.Īs we can see here SOLIDWORKS is able to accurately solve for the outlet velocity. In SOLIDWORKS We set the inlet boundary condition to 2m/s and the outlet to environmental pressure. Working this out by hand we use the equation:Īssuming the Density does not change we can remove and rearrange for V2 If the inlet velocity of the water is 2 m/s what is the velocity at the outlet? The reduction in area should lead to an increase in Velocity of the fluid. The nozzle above goes from having a 0.5m Diameter to a 0.25m diameter. With a few boundary conditions defined by the user SOLIDWORKS solves the equations for us. These are complex equations to solve for humans, luckily computers are excellent at solving equations. These equations solve for the continuity of mass and momentum and state that the mass times the acceleration is proportional to the force acting on a fluid particle.

Navier Stokes equation for incompressible flow in the x,y,z directions respectively. SOLIDWORKS flow simulation solves studies using the Navier Stokes equations which are outlined below. SOLIDWORKS Flow Simulation Vs Hand Calculations

0 kommentar(er)

0 kommentar(er)